One of the often overlooked benefits of an e-Auction program is the improvement in scopes of work. This is because when any qualified supplier who can provide the scope of work can participate in the e-Auction, suddenly the answer “my incumbent knows what we need” isn’t enough. An e-Auction process forces technical teams to write down what they need from suppliers and what the supply chain team must ensure suppliers deliver. Scopes of work, also sometimes called statements of work, are the document that describes what the company needs so the supplier can provide it. As a buyer, I was often asked by my internal customers if I had a template for a scope of work. While I could provide a “company introduction” section of a scope and a Word document with some pretty formatting, every scope of work for complicated purchases is different and has different needs. Instead of having a template, it was helpful to have technical teams instead answer a series of questions.

What do you need to purchase?

While this question seems obvious, it is the most logical place to start. The trick here is to focus on the true need and not what the incumbent supplier is providing or the method the technical team thinks is needed to deliver it. For example, it seems simple to write a scope requesting a Caterpillar D5 bulldozer. Is that what is truly needed? Or is the need for a piece of equipment that can move four cubic yards of material? Or tow twenty tons off road in rough terrain? Keep asking for the true need until what you have is a supplier-agnostic requirement. True value is created when suppliers can offer creative solutions in their area of expertise to the problem the company needs to solve. Suppliers should know more about their industry niche than the company purchasing the good or service.

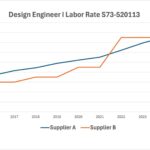

How much is needed?

Again, this seems like an intuitive place to start but is often overlooked. This category can include estimated annual or monthly volumes, but it can also include length of engagement for services, estimated number of hours, not-to-exceed volumes, or minimums. Be clear on what is an estimate and what is set. As much as possible, make the pricing schedule or bid price reflect the value of the full contract. If the bid is for a supplier partnership for five years on a widget that costs $5.00 with an estimated annual volume of fifty thousand, the bid should reflect the full value of $1.25m and not simply $5.00. A request to bid on something worth $5.00 gets ignored, but a bid for $1.25m does not.

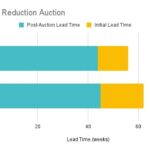

When is it needed?

When something is needed includes lead times and response times, as well as other timeframe-related parameters. This may be expected lead times or even how lead times will be contracted or communicated. The scope can include the lead time if a forecast is provided to the supplier, or the maximum acceptable lead time to win the bid. Or it can detail how to bid the lead time if lead times are part of the bid alongside pricing. In weeks? Days? Business days? Including shipping times?

For services, this might include the response time expected of the supplier. Is it expected a supplier responds within one business day? Four hours? That they have a person on the way to fix the equipment within a certain number of days or hours? Or perhaps the length of the supplier engagement, such as the timeframe for an intensive training program.

Where is it needed?

Avoid the temptation to require a supplier to be located within a certain number of miles of the company facility. If the concern is response time or lead time, that belongs in the “when” section. The section on where is about the location for delivery of the good or service. Which company facility or facilities will need the goods? Is the service or training program to be delivered in person or virtually? Is there an expectation the supplier will travel to the company for meetings or status reports? If so, what is the travel per diem or reimbursement policy? The key here is to focus on the true need for delivery and allow the supplier as much freedom as possible in meeting that need. I’ve seen multiple instances when the supplier located farther away has better lead times than the one nearby because the farther supplier has a better logistics network.

Why is it needed?

Why something is needed is an optional part of the scope of work depending on the material or service. To reach true supplier partnership, helping the supplier understand the why can be really helpful in letting the supplier propose solutions that reduce risk and add value for both parties. For example, if the supplier understands how their widget is needed as part of the overall product, they can propose an alternate material or solution at a lower cost that still meets the need. Or a services supplier who understands how the training they offer fits into existing programs can better tailor the solution to exactly what the company needs without frills. When including a “why” section to a scope of work, the buyer must be prepared to pivot, reissue the RFP, or otherwise modify the bid mid-flight if a supplier proposes something of excellent value that changes the scope of work in order to reestablish a fair playing field.

What criteria will qualify suppliers?

The qualification criteria is the most critical part of a scope of work that is heading into e-Auction. To improve the e-Auction process, the best criteria are those with crystal clear Go/No-Go or Yes/No answers. Any no-go answer to a criteria should be enough to disqualify a supplier from being able to compete in the auction, and they should be as objective as possible. Some examples of poor and better Go/No-Go criteria are below:

| Poor Go/No-Go Criteria | Better Go/No-Go Criteria |

|---|---|

| Supplier has sufficient experience to provide the scope of work | Supplier has been in business for at least 5 years and provides references for a similar project of this size |

| Supplier shall service equipment promptly | Supplier shall provide guidance to repair equipment via phone with a response within one hour of issue reporting, and shall provide in-person service within one business day if unable to resolve via phone |

| Supplier has reasonable contract terms | Supplier accepts all contract terms as written in sections 10, 15 and 18 of the contract and has minimal redlines to other sections |

What reporting is needed?

Reporting is how you can hold a supplier accountable for meeting the scope. What kind of reports do you want? At what frequency? Who are they written to? What information is required within them? The key here is to create reports that are useful and actionable, but are not too much work for the supplier to put together. I’ve seen multiple times when companies ask for lengthy reports that are too cumbersome to actually use. Keep it minimal, keep it simple, keep it actionable.

Contract Language

A note about contract language: keep it out of your scope if there is language in your contract template. Examples include payment terms, maximum package weights, change notifications, and the like. Because a good scope of work becomes “Exhibit A” or something similar in your contract, a conflict in terms causes legal headaches. While it is tempting to change these terms using the scope, change them in the contract documents instead to keep the legal requirements clean.

Who will receive the bid request?

Which suppliers are invited to bid is an important part of a conversation between procurement and the technical team, but is not technically part of the scope of work. Services like Scoutbee can help find suppliers if you are consistently having trouble finding suppliers for certain niche needs. My caution here is to not exclude a supplier simply because a technical team had a poor experience in the past, especially if that experience is more than five years in the past. For those situations, drill down to the true issue with the supplier (did they bite off more than they could chew? Did they leave a mess on the jobsite?) and write the criteria and scope of work to not allow the same poor behavior. If that unacceptable behavior is part of how that supplier does business, they will self-select out or be disqualified.

A good scope of work pays dividends in supplier clarity, accountability, and cost. Any time a company can reduce risk through certainty, both supplier and buyer will win.