“The 80/20 rule always applies” is a phrase I’ve lived with so long I don’t even know where I heard it first. But I’ve definitely repeated it – to my teams, to clients, to my poor family who are no longer at all interested (if they ever were). But what is it, why and how does it apply, and why should you care? The thing is, it governs your life whether you realize it or not, and you can harness its power if you know how.

Where We Find the Pareto Principle

The 80/20 rule is also known as the Pareto Principle and says that 80% of the consequences come from 20% of the causes. Another way to put this is that you get 80% of your outputs for 20% of your inputs. This shows up in sales (80% of the business comes from 20% of your clients), supply chain (80% of your spend is in 20% of your suppliers), fundraising (80% of your donor money comes from 20% of your donors), safety (80% of your incidents come from 20% of the hazards) and a myriad of other places.

The 80/20 rule also shows up in effort, and this is very important. If you are troubleshooting a computer program, fixing the top 20% of bugs that have the highest impact actually solves 80% of the program’s problems. Getting a PowerPoint deck to the 80% complete level requires 20% of the effort, while getting it the last bit of the way takes 5x the effort it took to get the presentation to “just good enough.” Often being a student in school is like this – getting a B- requires 20% of the effort that getting an A+ would in many cases (obviously, there are classes and topics where getting an “easy A” requires far less effort).

Wielding the Pareto Principle

So now that you know about the Pareto Principle (if you didn’t already), what do you do about it? Why do you care? First, apply it to your company. If you have control over a team and their time, direct them toward the top problems first to have the greatest impact. Resources are always scarce (see my article on change orders that talks about how people are goldfish). You will never have enough resources to solve 100% of the problems, bid 100% of the spend, or remove 100% of the risk. If you’re on the front lines, try to emphasize how much impact the team can have if they focus on the top 20% when those endless staff meetings are trying to talk about what the team will work on next. This also helps the team not go down too many “rabbit holes” or tangents.

The 80/20 rule can help you figure out when something at the company is “out-of-whack.” Are your customers or suppliers super-concentrated at the top or super-diffused so they don’t follow the 80/20 rule (more on the supplier side of this below)? Do you have a top-heavy organization where managers make up more than 20% of your org chart?

Apply the Pareto Principle in your personal life too. Can you get the kitchen to 80% clean in half an hour but to get it deep-cleaned would take almost three? Would getting the kids to pick stuff up off the floor of their rooms for 10 minutes make you satisfied enough that they could then get back to doing whatever they wanted to be doing instead? Could you vacuum only the main walkways and get that “clean house” feel you’re seeking? Now, what would you do with that extra time?

I’m not saying we never want things to get to 100%. Sometimes it’s an important board presentation that has to be just perfect. Or it’s been three years since you moved into the house and your baseboards are gross because no one ever does that last bit of cleaning to wipe them down. But before you go down a personal or professional rabbit hole and try to deliver perfection, ask yourself what’s “good enough” and if there’s something that adds far more value for your time. I used to say to my very first team, “I’d rather have cheddar on time than gouda late” and I meant it. That team even bought me a t-shirt with that phrase on it.

The 80/20 Rule in Supply Chains

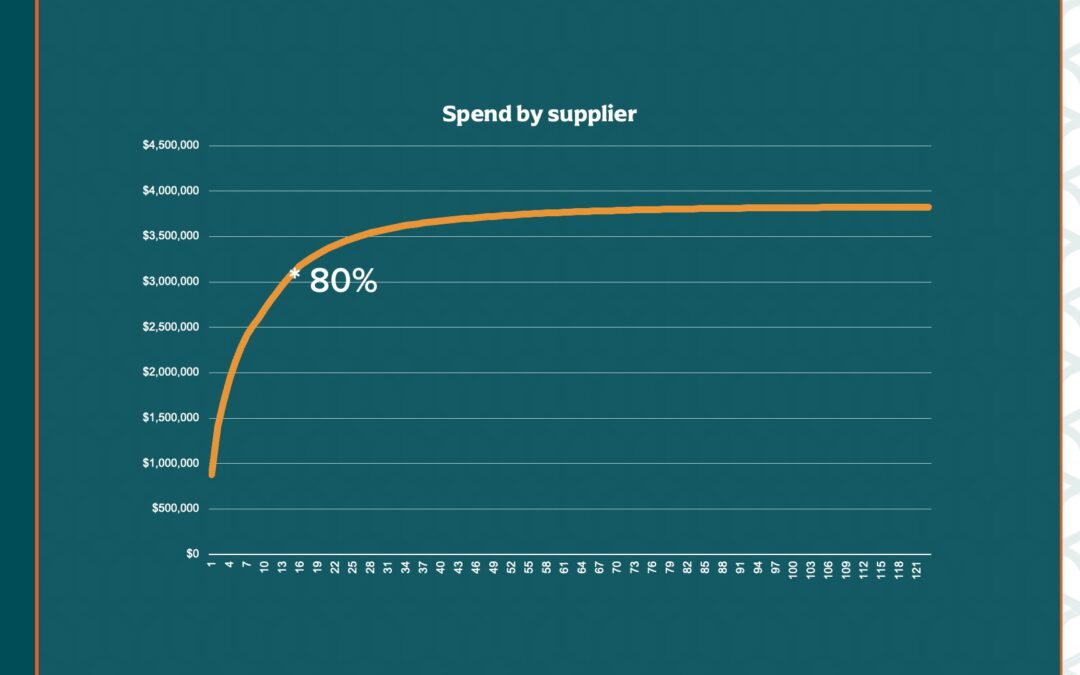

The 80/20 rule shows up in supply chains all the time. The most obvious applications are in determining which suppliers to partner with strategically and determining your tail spend. I’ve been working with a number of small, Iowa-based manufacturers recently and so I’ve been doing a bunch of spend analysis. I’m often finding that instead of 80% of spend resting with 20% of suppliers, these manufacturers are much more concentrated at the top with 80% of spend in 10 or 15% of suppliers. This means two things: first, they are carrying extra risk because their supply chain is likely in major trouble if one of those top two or three suppliers goes down. Do they have a secondary supplier strong enough to pick up slack? Second, it might mean they have way too much tail spend. If the bottom of a spend curve just goes on and on and on with suppliers having less than $100 per year in spend, that’s definitely a tail spend problem and needs to be managed as such.

The other place the 80/20 rule definitely shows up in supply chains is in e-auctions. First, the top 20% of e-auctions will hold 80% of your value in the form of cost reductions, savings, and even adding clarity to scopes of work. Second, there’s a huge practical application for individual auctions with lots of part numbers. If you run a Request for Proposal (RFP) ahead of the e-auction, you probably got pricing for all the part numbers in the bid. But that doesn’t mean everything has to go into a final negotiation or e-auction. Find the top spend items that truly “move the needle” and focus on those. That way, you’re not setting up an e-auction with 150 parts for suppliers to enter pricing (yikes! What a slog for both sides!) and you can really focus on the parts that matter. The 80/20 rule says it will be about 30 of them, which is much more manageable.

Now that you have the basics of the 80/20 rule, take a look at your life, schedule, and work and see where you can apply it. Are there meetings hanging on your calendar that are in the “80% unproductive” category? How can you make them shorter, more efficient, or gone? If you’d like a hand with your spend analysis, building e-auction lots, or just to say hello, let’s chat.