Like any industry, procurement has its lingo. RFP, RFI, RFX, bids, suppliers vs. vendors (that’s a whole other topic!), maverick spend, cost avoidance, tail spend, e-auction, TCO, punchout, and a myriad of other things. But presiding over all of these other terms: Direct and Indirect Spend. In procurement we love to classify things. When I was new to procurement and supply chain, the terms direct and indirect mystified me. Why do procurement teams use them? What do they really mean? And most importantly, why do they matter? Talk to any procurement professional who has been doing category management for a number of years and they are likely to have an opinion on their favorite set of categories between direct and indirect. They may even talk your ear off for a while on why they love their chosen division. So let’s talk today about what direct and indirect spend is, why this classification (or a similar one) matters, and the skill sets needed in each to succeed. I’ll also talk a little about the push and pull between business unit and procurement team responsibilities, especially in the indirect space.

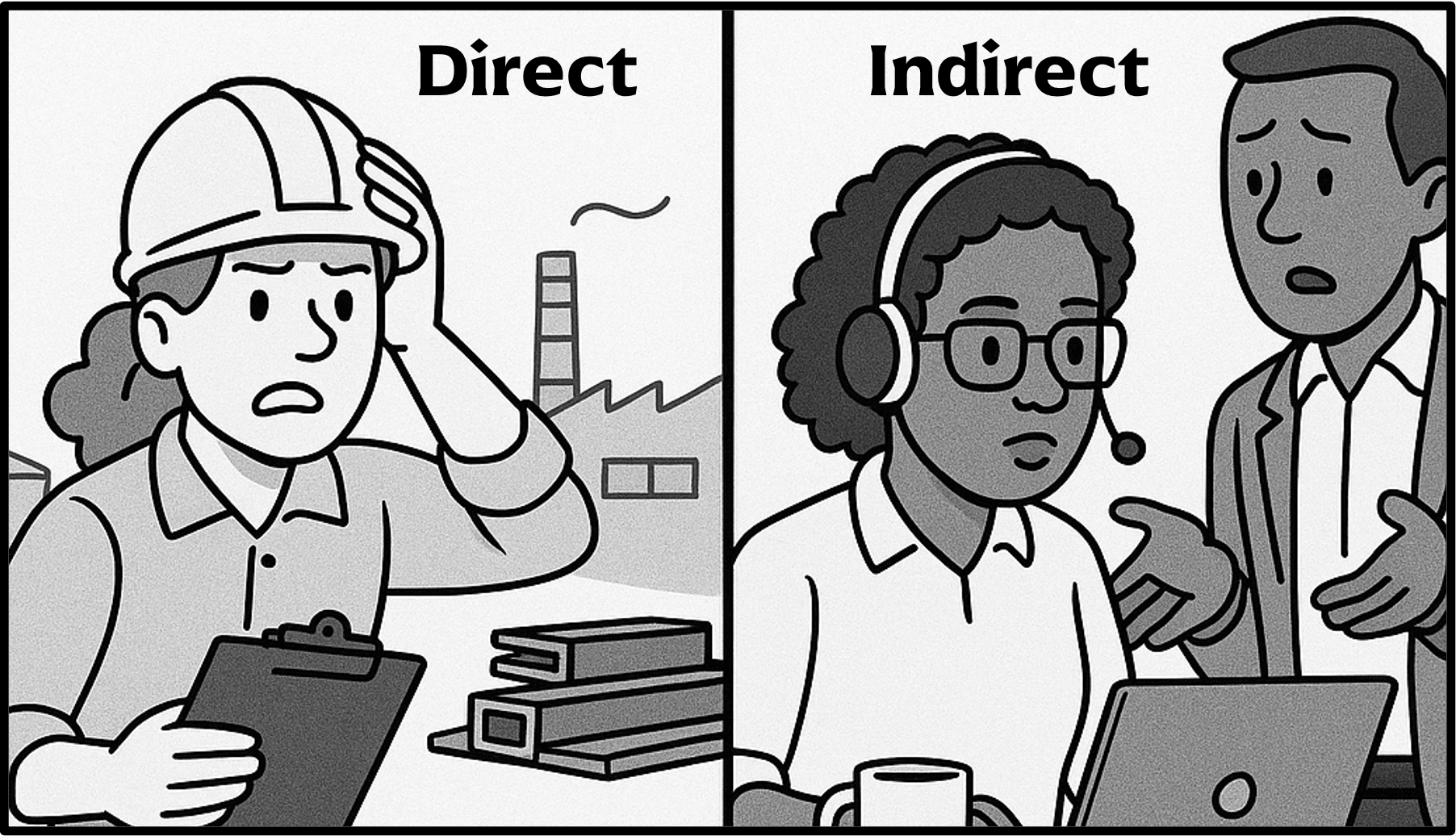

Defining Direct and Indirect

Whether a spend category is direct or indirect has to do with the product that goes to the end customer. Direct spend categories are those that go directly toward building the product a company sells. In manufacturing, this would be the subassemblies, components, and machinery needed to produce the product. In a services industry, direct spend would be the labor or even external “billable hours” to produce the result for the customer or client. In construction, direct spend is both the subcontracted labor and materials that go into the final construction project to be handed off to the customer.

Here are some further examples of direct spend:

- Steel castings

- Drill bits or other tooling used to create a product

- Plastic pellets for an injection-molded plastic plant

- Lumber for a construction project

- Billable hours from a law firm subcontracted to another law firm

- Database memberships (for a service firm providing research)

Basically anything an accountant might classify as “cost of goods sold” is likely to be direct spend.

Indirect spend is all of the spend that indirectly supports the creation of the end product that goes to the customer. This includes maintenance, human resources, usually IT software and hardware, accounting and finance, and any other support functions.

Here are some further examples of indirect spend:

- Employee benefits

- Plant maintenance, lawn care, and snow removal (if outsourced)

- Employee laptops

- Safety gear

- Components, like belts, to repair machinery

- Financial audits

Indirect spend tends to be more services than materials and the line between direct and indirect can get very fuzzy very quickly.

It is very common for procurement teams to divide the team into team members who support direct spend categories and those who support indirect spend categories.

Side Note: This classification method breaks down rapidly in an electric utility because of the nature of the business. The deliverable to customers is power, and the only true direct spend is the coal, gas, or nuclear fuel to produce that power. Even more tricky, the inputs for solar, wind or hydroelectric power, are essentially “free.” In addition, the coal, gas or nuclear fuel are purchased on commodity markets and are a whole different process done by a whole separate team from procurement. So utilities will often use materials vs. services instead of direct vs. indirect to classify their spend.

Why Direct and Indirect Classifications Matter

So why do we even care about direct vs. indirect spend? The delightful Joël Collin-Demers had a great post a few months ago about direct vs. indirect spend and whether each classification needed its own procure-to-pay software. When asking about the difference between direct and indirect, Joël cites the difference as “The experience around the transaction!” He goes on to say that:

“For direct purchases, you:

→ Can automate lots of it with Materials Requirements Planning (MRP)

→ Want to keep most if not all of it in inventory

→Want to create material master records to build BOMs and retain important information

For indirect purchases, you:

→ Are extracting requirements from a requester’s head

→ Expense most purchases up front with no inventory management

→ Want to avoid managing materials and price records because the prices always change”

This is a great summary of the differences between direct and indirect as they impact the procurement team. We use this classification in procurement because direct and indirect spend needs to be handled differently. Some further differences between the two include:

- Velocity – Direct purchases simply move more quickly than indirect. Lacking a direct material will create downtime on a manufacturing line. Being unable to provide the right construction labor results in a delayed project. When something goes wrong with direct spend, it seems like everyone knows and every executive cares.

- Leverage – Direct purchases tend to have more leverage with suppliers than indirect purchases. These purchases are core to your business and what it provides to your customer, therefore they get more attention and more effort to put together a competitive field of suppliers wherever possible.

- Spend – Direct purchases tend to have more of the spend. Sometimes this means indirect spend takes a bit of a backseat to the larger and “more important” direct spend. Often the team who supports the direct spend carries more weight in an internal procurement discussion (whether they realize it or not).

- Certainty – Direct spend is more certain, in both scope and quantity. While estimates can be wrong and markets can change, there is usually a pretty good idea of how many materials a company needs to buy in order to sell their target number of finished products. Often the requirements for indirect spend (including estimated volumes) are soft, fuzzy, and vague.

Perhaps you’ve picked up on this by now, but I’m an indirect spend lover myself (if I have to choose). While I have experience with and can do both direct and indirect, I have a soft spot in my heart for those weird categories that need ridiculous amounts of creativity, cajoling, and even frustration to find value.

Skill Sets Needed

How do these differences matter to you, the procurement professional reading this and trying to navigate their career? Especially if you’re early in that career or if you’re a hiring manager trying to round out your team or replace someone who has moved on to greener pastures. The answer is that direct and indirect spend take different skill sets to manage. Supply chain teams are full of all kinds of personalities, and some personalities are better- or worse-suited to different categories.

For direct spend management, you need:

- Tough negotiators – the kinds of people who don’t take no for an answer and can squeeze every penny out of a supplier

- Analytical minds – team members who are constantly calculating dollars and quantities and can still remember key part numbers from five years ago do well in direct procurement because it tends to be a world of numbers

- Operations-focused – direct spend category managers if they truly understand what drives a business. Those who can keep in mind, which products are actually important and which ones just have floor managers who make a lot of noise?

For indirect spend management you need:

- Influencers – these team members are constantly fighting the business unit to keep management of the categories within procurement, so they have to be able to fight that well, without any direct lines of supervision

- Patient behind-the-scenes cajolers – a superpower for an indirect category manager is someone who can plant the seed of an idea and then water that seed until it blooms. I always admire people who are good at making the internal customer think something was their idea

- Creative – team members who manage indirect spend have to be among the most creative and not intimidated by “we’ve never done that before.” These are the people whose response to “we don’t actually have any process for this and have no idea how to approach it” is “Awesome! That means I get to do it my way!”

When managing a team of both direct and indirect practitioners, one of the hardest things to do is have clear boundaries and delineations between responsibilities. Is IT hardware direct or indirect, and who handles it? Even more difficult, how about IT software, especially when it includes software that runs the machines on the shop floor making the product? There isn’t necessarily a right answer, but there is definitely a clear one and that clear answer is badly needed.

Business Push and Pull – Who Handles What?

Most direct spend is handled by procurement and the business units typically accept that responsibility. Indirect spend is more difficult. Who handles IT software purchases and negotiation? What about retirement account management and employee health benefits? It’s incredibly common in midsized (and even large) companies for the HR, IT or finance team to handle their own purchases and for procurement to not even be aware they exist. However, I can’t tell you how many times I’ve seen a procurement team get involved in these purchases and immediately find value. When 401(k) management came into the procurement space, at one company, the category manager negotiated management fees down from $26 per employee to $18. While that doesn’t sound like a lot, across 25,000 employees that represented $200k in very tangible value in addition to the other benefits they negotiated (more one-on-one appointments with employees about their accounts and better technology to support retirement investments). Procurement teams are trained negotiators who definitely do more than “buy stuff” and can truly use those skills to benefit any purchase a company makes.

So in determining where the procurement responsibilities end and the business unit responsibilities begin, ponder the following questions:

- Where is the current line on who handles what, and what is not handled by procurement?

- Where does the company want that line to be? Where does the leadership team want it to be? (They probably haven’t thought about it)

- How does the company define value for indirect categories? Is it cost only? Cost and service? This is important for determining if the procurement team is getting the value the company desires and is aligned with company goals. Value in direct materials is usually very clear (cost, quality, lead time; the iron triangle). But value in the indirect categories is less clear (maybe cost, delivery method, customer experience?)

Direct vs. indirect spend is supply chain jargon. But it’s jargon that matters and it’s helpful for every department to understand the differences, how to categorize their spend, and how they define value and success in each space. If you would like to talk about your team’s direct vs. indirect spend management, let’s chat. If you’d like to get these articles weekly straight to your inbox and never miss one, sign up for my newsletter.

My book, Transform Procurement: The Value of E-auctions is now available in ebook, paperback and even hardcover format: https://www.amazon.com/dp/B0F79T6F25