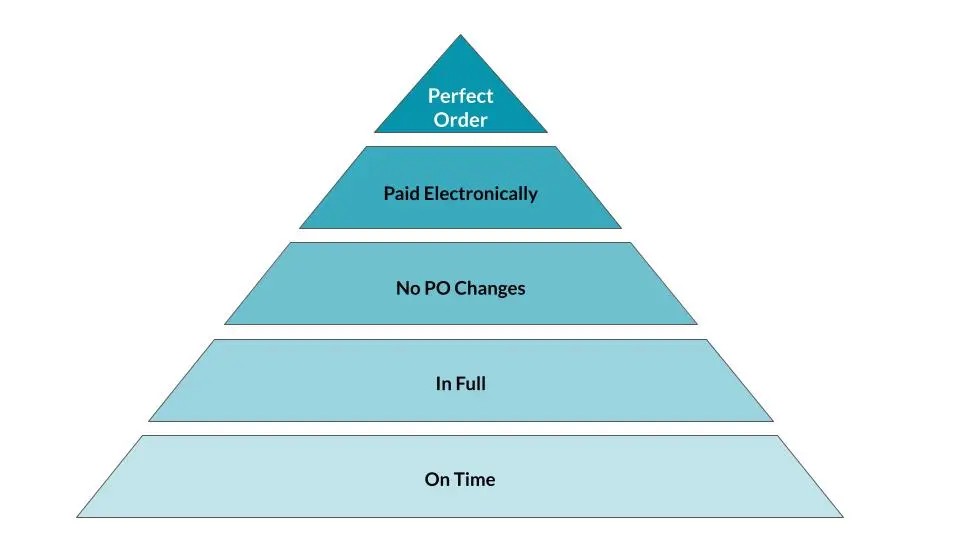

What is a perfect order? And why is it relevant?

Of all supply chain metrics, the pinnacle metric is the perfect order. It serves as a comprehensive measure, encompassing critical components that lay the groundwork for supply chain efficiency. A perfect order is an order that is delivered on time, in full, with no edits to the purchase order, and is paid on time electronically. In this article, we will delve into the key aspects of a perfect order and explore why it holds such relevance in the world of supply chain management.

On-Time Delivery

Defining on-time delivery involves careful consideration of a company’s receiving process, specific needs, and overall supply chain maturity. Striking a balance is crucial, as excessively early deliveries can inflate inventory and carrying costs. While operations frequently favors swift delivery, it’s important to note that true on-time delivery doesn’t entail significant early arrivals. For businesses focused on inventory control, considering a 2-4 day early window as “on time” may be prudent.

Addressing late deliveries requires a decision on what constitutes tardiness. Should the metric consider a prolonged receiving process, or strictly measure supplier performance? Opting for a comprehensive approach implies basing late orders on zero or less than one day late, measured by the receipt date. This then includes both the supplier timeline for delivery and the warehouse receiving timeframe. A more lenient approach might involve a grace period of 1-2 days to allow for internal receiving, without divulging this information to suppliers to prevent misuse.

In Full

A perfect order demands completeness, correctness, and avoidance of overshipment. It entails delivering the right parts in the correct quantity, adhering to the order specifications, and ensuring accurate labels. The absence of extra parts or shipment splits contributes to a perfect order. Barcodes, if the company uses them, should be present, accurate, and scannable for efficient receiving. While “On Time in Full” (OTIF) is a widely-used metric, the concept of perfect orders as a pinnacle metric extends beyond OTIF.

No Purchase Order Edits

Many modern Enterprise Resource Planning (ERP) systems can track edits to purchase orders. Any edit introduces additional work and hampers process efficiency. Price changes necessitate reapproval, quantity adjustments involve warehouse or inventory yard teams, and alterations to description or category require input from category managers. Changes to the due date can disrupt production schedules. Using ERP systems or process mapping software, such as Celonis, becomes imperative for tracking and enhancing efficiency. Recognizing that even seemingly minor edits incur costs is crucial for maintaining a perfect order and driving continuous improvement.

Paid Electronically On Time

The journey towards a perfect order culminates with the timely payment of the invoice. This requires adherence to contracted or system-entered payment terms (not those listed on the invoice) and electronic payment methods. Clean accounts payable processes, correct invoices, and matching payment terms between the system and contracts are imperative. In the digital age, electronic payments offer increased security and efficiency, outweighing the drawbacks of physical checks. If using electronic payment, ensure a robust process for changing payment methods to prevent fraud. Examples include having a contact to call to verify banking changes listed in the signed contract, or requiring a certified mail exchange.

Overall Metric

Combining these components enables the tracking of perfect order percentages. At the start of tracking this metric, initial perfect order percentages may be near zero. Keep the focus on continual improvement and identifying the root causes for near-perfect orders. Whether it’s material accumulation in receiving, fluctuating prices, or unreliable supplier lead times and forecasts, measuring and enhancing the perfect order metric aims to better serve stakeholders and optimize the entire supply chain.