Ah, change orders. While it is often necessary to change a project (and therefore change pricing) while that project is ongoing, change orders are frustrating for everyone involved. Large change orders can cause a blame game where everyone in a company blames everyone else for cost overruns. So how can a supply chain professional help prevent change orders, knowing they have limited control over a scope or project management process?

Process Control

The first step in mitigating change orders is to simply have a process for changes to a project. Who should approve a change? What paperwork is needed? At what level does a change trigger a new RFP? Consider these questions and write a procedure using whatever format your company prefers. When you write this process, make it a bit painful. While as supply chain professionals we want to provide good customer service, change orders should be a little bit painful so that only the changes which are truly needed go through that process. Try not to mire the process down in too much paperwork, but do consider making the approval levels a little higher than you normally would. If a $25,000 purchase typically requires the approval of a Director, perhaps a $25,000 change order requires a Senior Director or VP. Or perhaps a change order requires the approval of both the supply chain and business unit Director. Once your procedure is written, get buy-in and feedback from the business unit’s leadership. Do this early, and if possible have someone from the business unit write the procedure with you.

Make sure the change order outlines the cost of the change. Every change costs something, even if that cost is time or pizza. I had a supervisor who once told me he had a change that cost giving the project crew pizza to simply calm their ruffled feathers. If the change costs time, convert the time to dollars using your average loaded labor cost (loaded meaning include benefits, overhead, etc.). Typically that is up to 60% on top of a person’s salary, so an employee making $80,000 per year would have a loaded cost of about $60 per hour. I often use $100 per hour for this purpose to cover all the administrative costs, etc., and because it is a nice round number that is generally accepted.

Scope of Work and Contract

If you’ve been reading my articles for any amount of time, you know I am going to tell you that a good scope of work is a critical part of change order mitigation. While unexpected changes do come up (why is there rock along this drilling route not shown on the geological survey all of a sudden?!), the more risks and expectations that can be addressed in the scope of work, the better. If the project is large enough to have a project manager, make sure they create a risk matrix and then address as many of those risks in the scope of work as possible. This costs a little more time up front in a project, but more than makes up for issues later.

When you’ve completed the RFP, include change orders and their process in your contract documents. An example of this kind of language for manufacturing is found here. If you have a clean procedure document outlining the steps from a supplier’s point of view, include that either in the contract language or as an appendix. If you don’t yet have that procedure document, consider writing one that can be published on your website or included in your scope of work. The better suppliers understand your change order process, the more likely they are to not assume they can just slide changes through informally and “lowball” offers in order to buy the business. We want our suppliers to offer good value, and having them bid low just to create a bunch of change orders serves no one.

Governance

Now that the scope of work is as accurate and complete as possible, your suppliers and internal customers understand the change order process, and your contract includes all the relevant information, it’s time to govern change orders. First, use a purchase order to outline the project cost in accordance with the RFP and contract. While this may seem intuitive, I have often seen companies simply cut POs as invoices come in from the supplier instead of allocating the project budget to a PO ahead of time. Paying invoices as they come in is a difficult way to govern a supplier relationship.

Be thoughtful about whether your company will allow a PO or blanket PO to be written for more than the RFP proposal amount. It is tempting and common to include a level of overage in a PO, such as a 10% contingency so the internal customer does not have to come back to the supply chain team to modify the PO in the event of a change. However, people are goldfish. Goldfish will grow to the size of their bowl, and I guarantee at least part of that contingency will be spent. The supply chain team works hard to get the lowest price from the best supplier and throwing 10% on top of that carefully negotiated price erodes those efforts.

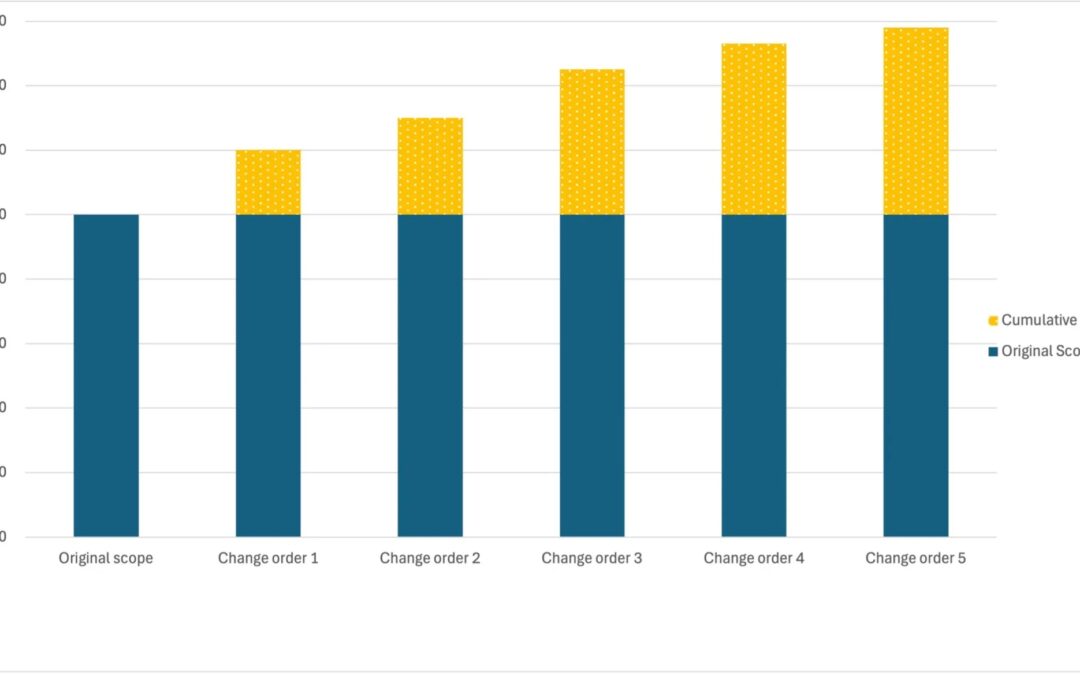

The last piece of governance is metrics and making change orders visible. When the business uses your change order process, make the results visible to the operations team especially. While we track many metrics within the supply chain, make sure this one is visible to the leadership of the group initiating and using the change orders. The budget ultimately belongs to them, but the supply chain team has visibility to the numbers. Do your best not to “become the police force” in enforcing change orders, let business leadership do that. Simply make it easy to see and manage when certain projects or teams have consistent overruns.In review, the supply chain team has a limited but important role to play in preventing change orders. Make a process, make it a little bit painful, write it alongside your internal customer, and make it visible. Then help the business write a strong scope of work and put the change order process into the contract. Lastly, don’t include contingencies in POs and make change orders visible to the relevant stakeholders. All of these actions can add up to reduce project change orders and therefore increase business value. If you’d like to talk to me about your company’s change order issues or process, let’s chat.