The award for “most eye-catching headline of the week” in my news feed goes to sponsored content from GS1. The headline was “Stop doom-scrolling your supply chain” and (as sponsored content) is advocating for increasing visibility tools. The article cites three main areas of supply chain concern remaining: geopolitical factors, climate change/natural disasters, and logistics labor shortages. This article highlights these items and GS1’s recommended actions, but it is also a call to action to look at your own supply chain cycle first before implementing another software package.

Geopolitical factors

The current geopolitical supply chain risks are primarily terrorist attacks in the Red Sea, ongoing war in Ukraine, and an uncertain China-Taiwan relationship. Geopolitical risks are not new to the supply chain. In the last twenty years or so we have dealt with wars in Iraq and Afghanistan, a trade war with China, the rise of cybersecurity terrorism, pirates near Somalia, multiple coups and major political changes in South America, U.S. political movements such as the 99% movement, Me Too, and Black Lives Matter, a major economic recession, and of course, a global pandemic. My point is that being a supply chain professional is dealing with geopolitical issues.

Climate change and natural disasters

The most prominent concern in the climate arena deals with water–either too much or too little. The Panama Canal is low, restricting traffic by nearly 40%. Hurricane season is now a major consideration, especially with many U.S. chemicals coming out of Houston, TX. Flooding in SE Asia in 2022 and 2023 slowed shipping of semiconductor chips, but that same industry also needs large supplies of water to manufacture. Unlike geopolitical factors, this is fairly new to the “list of supply chain worries,” but has also been predicted for some time.

Logistics labor shortages

After COVID shook up workforces everywhere, it is clear the labor market has changed. The pandemic caused a huge wave of retirements, and continues to fuel the work-from-home/work-from-office/hybrid debate four years later. A Descartes study cites 37% of organizations experiencing workforce shortages, especially in transportation operations/logistics. While there have been labor shortages before in most areas of the world, this one may take a little time to work through. Analysts have been predicting labor shortages once the boomer generation retires for many years, and recent Artificial Intelligence gains can only do so much to mitigate the impact.

What to do?

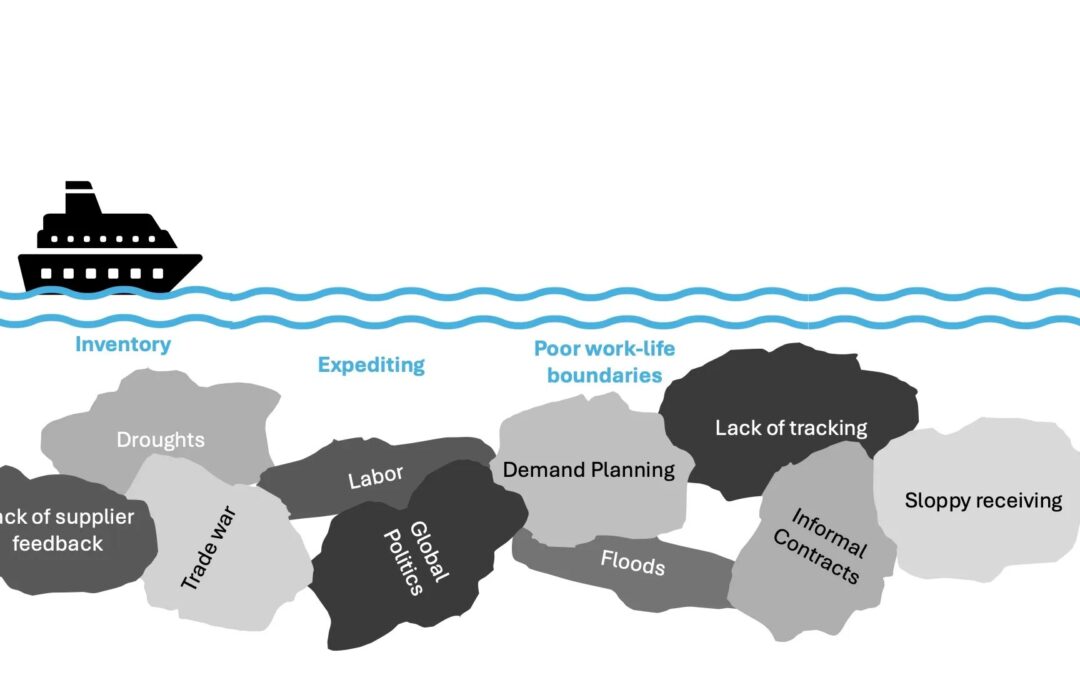

COVID lowered the waterline enough to make the rocks always under the supply chain waters visible. These issues used to hide under inventory, suppliers willing to expedite materials to shorten lead times, and traveling account managers who were willing to answer their phones at all hours of the day. After COVID, inventory is depleted, shipping lanes lack the space for last-minute expedites, and account managers are putting human boundaries on their time as we all focus on better work-life balance.

The GS1 article cited at the beginning of this article recommends three actions:

- Diversification and healthy redundancy – Dual source where you can, and diversify the global region origins of those items when possible.

- Predictive analytics, risk assessment, and scenario planning – Analyze the supply chain to understand where materials in transit are, how they travel, and their costs. Run simulations to plan various scenarios.

- Agile decision-making – Collaborate with operations and key suppliers to pivot more quickly when something goes wrong, and empower local teams to make decisions.

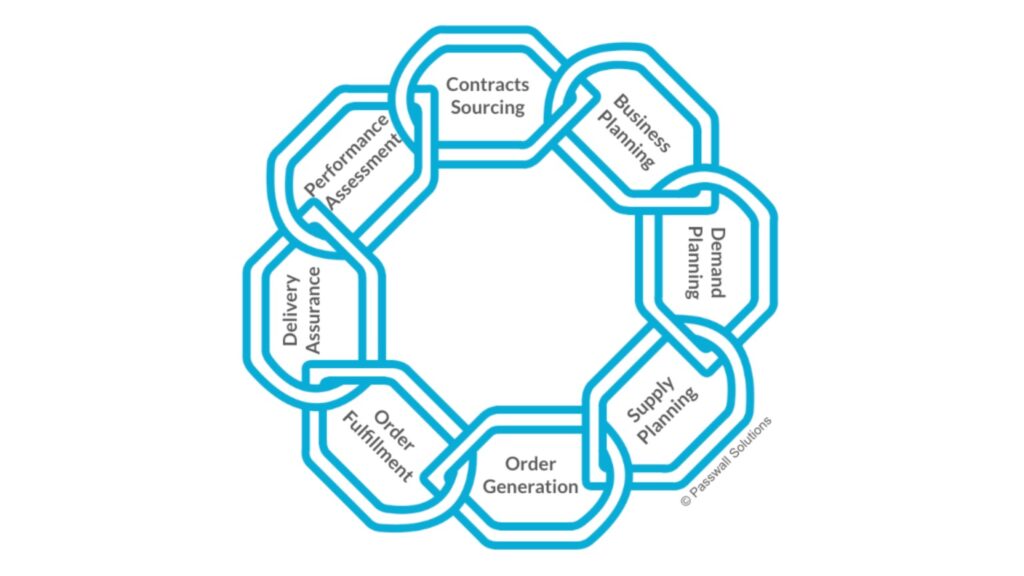

I will add that many supply chains are not completing the whole supply chain cycle or are not doing it well. Poor demand planning, informal contracts, lack of supplier feedback, and a sloppy receiving cycle can all contribute to a struggling supply chain. Conducting a Supply Chain 360 audit can be a great place to start if your supply chain still feels “broken” and you don’t know why. Whatever you decide to do, start with the supply chain basics and build from there. Turn your worries into action.