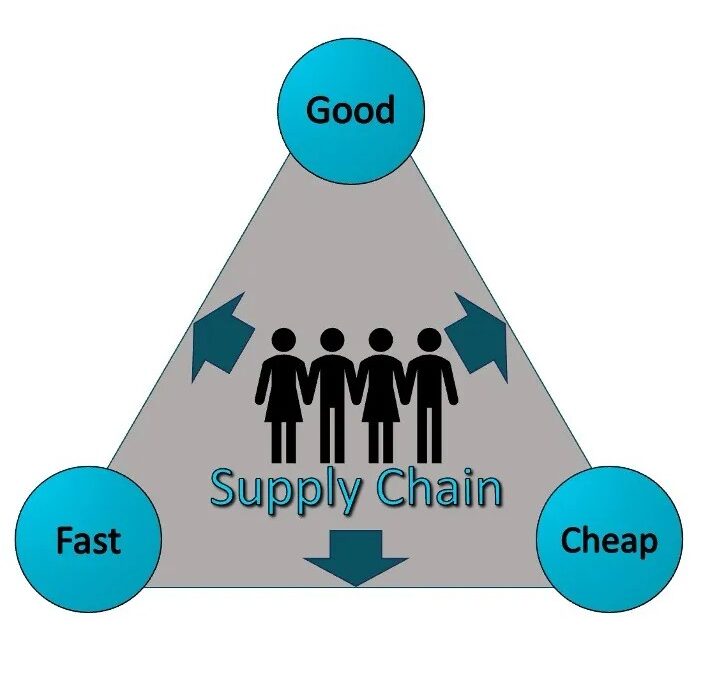

“You can have it fast, you can have it good, you can have it cheap: pick two” is a very old phrase for any purchase, and is a central tenet of supply chain work. While in a previous supply chain leadership role, my company had a major shake-up in senior leadership. As a result, one of the first things I was told by my new management was that the supply chain team had its priorities all wrong. This clarified for me the variation on the “Good-Fast-Cheap” triangle, also known as the iron triangle, where any supply chain team ultimately focuses their efforts in one of three places: Delivery, Savings, or Efficiency. Because all efforts by the team go toward one of these priorities, it is helpful and important to fully understand each of them and align the order of the priorities to those of the senior leadership team.

Delivery: Ensuring Goods and Services are Delivered at the Right Time and Quality

The delivery priority is a focus on the tactical part of the supply chain, the part that most of the world thinks of when it thinks of a supply chain. These are the activities that ensure goods and services are delivered at the right time and expected level of quality. On the iron triangle, delivery is motion toward the two points represented by “Good” and “Fast.” These tasks look like cutting a high volume of POs, expediting shipments, heavy tracking of inbound and outbound logistics with real time data, and constant following up with suppliers for inbound shipments to ensure they will be delivered on time as expected.

Savings: Ensuring the Best Price for Goods and Services

A focus on savings is what many supply chain practitioners think of when they think of supply chain. This priority makes sure the business does not pay more than market rate for any good or service, and wherever possible pays less than market rates. On the iron triangle, this is an emphasis on the “Cheap” side, with some companies then also focusing on either “Good” or “Fast” depending on their business model. Tasks that support this priority look like constant in-depth supplier negotiations using e-Auctions and other negotiation tools, running requests for proposal for even small purchases, writing strong contracts, ensuring suppliers have long payment terms and are not paid early, using sophisticated spend analysis tools and bidding software, heavy tracking and reporting of savings and cost avoidance to upper management, and constantly pursuing a Purchase Price Variance (PPV) of zero.

Efficiency: Ensuring Supply Chain Work Gets Done with the Fewest Resources

Efficiency as a priority focuses on achieving supply chain results with the fewest possible inputs. This internal metric measures the supply chain headcount and supply chain budget, and is what supply chain management often thinks about when they are thinking of their supply chain teams. On the iron triangle, this represents the middle and the resources trying to achieve the Good/Fast/Cheap results for the business. Tasks that support this priority include requiring justification to replace any person who leaves the supply chain team (and never adding team members), supply chain leaders managing 8–12 direct reports, minimal travel, few “extra” software tools, and extensive process mapping or similar continuous improvement initiatives.

How Priority Order Manifests in Business

Every supply chain has an order of priority between delivery, savings and efficiency, and the order determines the supply chain team’s culture. A team that prioritizes delivery will have a lot of buyers and expediters, will track on-time delivery (or on-time-in-full) extensively, and will reward the team members who “get stuff done” most. A team that prioritizes savings will have a lot of category managers and analysts, will track savings and cost avoidance meticulously, and will reward the team members who put up big numbers on the (likely very visible) savings board. A team that prioritizes efficiency will be small and include a variety of roles, will track metrics on a per-person basis (such as number of POs cut per buyer), and will reward team members who find ways to automate or remove tasks.

The tricky part of all of this is that executive leaders want all the priorities to be the priority. Just as with the iron triangle, movement toward one priority tends to move a team away from the other priorities. While balanced outcomes are desirable, an order will establish over time. What happened in my case was that new leadership coming in wanted a different order than the previous leadership, and the transition to a new priority order is difficult and painful at best. The best outcome is when the CEO of a business and the supply chain leader are aligned on the order of priorities between delivery, savings, and efficiency.