Allow me a moment of self-indulgence, as I review this past year. This post may also be a bit more personal than most and is a chance for reflection. 2024 was a good year for Passwall Solutions, and I’m proud of the work I have done.

I am still a solopreneur, not yet having hired any employees. I’m still not sure if I will, or if I will simply keep being responsible (professionally) only for myself. While I enjoyed being a leader of a 150-person supply chain team and standing among my global team as they worked away on creating and capturing value for our business, it’s also nice to have perfect alignment between my vision and my “team’s” vision.

I met my revenue goals for the year, which is very gratifying. While I am not yet “ramped up” to my full capacity or revenue, I am busy right now. One of my network contacts who runs Leverage4 told me contractors/consultants are considered at capacity when working 26 hours per week, which is about where I currently sit. I had a total of seven clients in 2024, three of which are currently active. To my surprise, clients were all over the US and even reaching globally.

Clients

My first client is a large utility construction firm with offices I visited in Phoenix, Las Vegas, and Dallas. They called me when their procurement team was minimal (1 person) and most procurement activity was done by project managers. They needed some help standing up a team so they could better serve their customers. I completed some process mapping, did a Supply Chain 360 assessment to find their areas of strength, and started planning a procurement team. I also helped them respond to multiple customer bids, assembling the procurement component of sales presentations and coordinating supplier bids received. They now have a Director in place and a team of 7-8 supply chain professionals in various roles, off and running on meeting the organization’s needs. More on building a supply chain team can be found in my article here.

My second client is a family-owned manufacturer in Des Moines with a long history and a need for some process improvement. While I initially expected to rework their purchasing processes, we quickly discovered a larger need. After putting together a cross-functional team, we mapped the sales-to-ship process, purchase order to production order process, and the production of their most commonly built machine. This was like building a 50,000-ft view, 5,000-ft view, and a 5-ft view of the company, and the team really started to understand how their own work affected those upstream and downstream. We even walked the production process on the shop floor to understand just how much parts were moving around and where the waste was. The great part of this work was that we could focus on the processes that were broken or unclear without turning it into a huge, multi-year Lean Journey. The team’s feedback from those sessions was that it really helped people to see what other areas (sales, accounting, purchasing) were dealing with in their day-to-day and could use that information to be better colleagues and partners.

My third client is an aerospace distributor out of Los Angeles who was onboarding a new COO. The Supply Chain 360 was especially helpful to their business leader and their new COO because it gave them a clear and complete picture of their supply chain on Day One in the role. We got to work mapping their processes (remotely!), from the warehouse to quoting to accounting. Within a couple of weeks, we had those processes mapped and much more clarity in the team on who did what and when. As a result, they improved their customer on-time delivery from 65% to 82%, improved their incoming delivery by 10% due to better receiving processes, and reduced their warehouse work in progress inventory from $300k to $50k. Together we put together a training program for their quoting team, and now they’re turning around more quotes and capturing more business than ever before.

My fourth client is a publishing material distributor out of Des Moines with a new CEO. That CEO wanted a clear picture of their supply chain, contracts, and supplier relationships before launching into any reforms or changes. He was able to move forward with that clear picture of his supply chain and start tackling difficult supplier relationships alongside his existing team. Next we process-mapped their customer service team’s daily activities from billing to quoting to order entry and scheduling. Through mapping these processes, we generated more than thirty concrete improvements to streamline, reduce paper usage, increase value-added activities, and spread the use of best practices.

My fifth client is the result of a partnership with the German firm Kloepfel Group for a chemical manufacturer out of Houston. The client has branches in both Germany and the US and I am leading the US component of the project. The target is saving the client money in their indirect supply chain, with a goal of saving $10m over the next 14 months or so between both locations. This project is still ongoing, but has been an interesting foray into this part of supply chain work. I’m optimistic we can get great value for this client.

My sixth client is a window manufacturer out of Phoenix with a very young supply chain team. Most of the six-person team is within their first couple of years in a supply chain career, so the focus has been on training them in the larger supply chain picture and how much opportunity there is in our world to bring value. After an initial training on the full cycle, we’ve done deep dives on performance assessment, sourcing, and order generation and are about to do in-depth reviews on their category strategies. This work really got the team talking about their work and energized to move beyond the transactional day-to-day supply chain activities.

My seventh client is a utility out of Columbus, Ohio who is looking to implement e-Auctions. We’re just at the beginning of this journey for them, but I’m excited to get negotiations back into their bid processes and really capture value for their customers. We’re going to get them up and running with e-Auctions in months where it first took me years, and we’re doing it with change management firmly in place. Right now we’re expecting to reduce their RFP pricing by more than $100m and find cost savings from historic or budget pricing of at least $9m annually.

Writing

Implementing e-Auctions is also the subject of my book, scheduled to come out in about May 2025 and published by Red Thread Publishing. I completed my first draft in May 2024, sent it through a professional editor twice for review between May and October (Jessica Burdg – I highly recommend her if you’re looking for some help with your own work!), and signed a contract with the publisher in November. Forward!

I’ve also completed an article every single week this year, including on Christmas Eve (that one is about buying a live Christmas tree if you missed it!). My top articles according to LinkedIn impressions were:

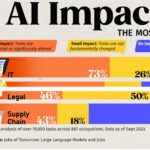

- Robots vs. Relationships: Will AI Wipe Out Supply Chain Jobs?

- C-Suite Smackdown: Where Should Your Supply Chain Leader Report?

- Guide to Dubai for the Female Professional

What an interesting cross-section of articles! AI, of course, is a hot topic right now, so it’s not a surprise to see that one there. The C-suite smackdown series is interesting, and I think it’s here partially because I didn’t see a lot of others talking about this topic. In the post-Covid reshuffling of organizations, supply chain leaders are trying to figure out where they best “fit.” The traditional org chart with supply chain fitting under the CFO doesn’t always work anymore, and companies are experimenting with putting the supply chain under operations or directly reporting to the CEO.

The guide to Dubai for a female professional doesn’t really surprise me either, as I think it fills a bit of a gap. It was certainly an adventure I didn’t expect and the courses I recorded for SCMDOJO are available for those wishing to learn about supply chain topics. As I said in the article, I went looking for a guide like mine and was disappointed by not finding much. Hopefully this guide helps someone, and at the least it is very full of beautiful pictures of a beautiful city.

I’m looking forward to what 2025 brings as my business enters its second full year and continues to mature. If you would like to talk about your 2025 goals, if something sparked you in what I did for clients in 2024, or if you simply want to bounce some things off me, let’s chat.