The most common question, especially at conferences and networking events, is “What do you do?” In casual settings, my answer is “I solve supply chain problems.” At networking and professional events it’s often, “I bring negotiation back to procurement” or “I elevate supply chains.” All of these are true. They’re also a bit short and incomplete and it’s hard to really tell people what I do in most settings. Last year I wrote an annual summary and many people commented they liked reading it and figuring out what I actually do every day. Today let’s talk about the kinds of companies I helped, with what problems, and to achieve which results. I’ll also talk about my top posts on LinkedIn (there’s so much chatter about that algorithm on that platform right now, and whether there’s a bias away from female authors!), my book, and a few other odds and ends. So if you’re interested in what I actually DO daily, read on!

Clients

I had about three clients active when I started in 2025. This was my second full year in business, and I’m finding roughly three clients at once is my capacity. This is especially true when all three are doing big savings initiatives or implementing e-auction programs.

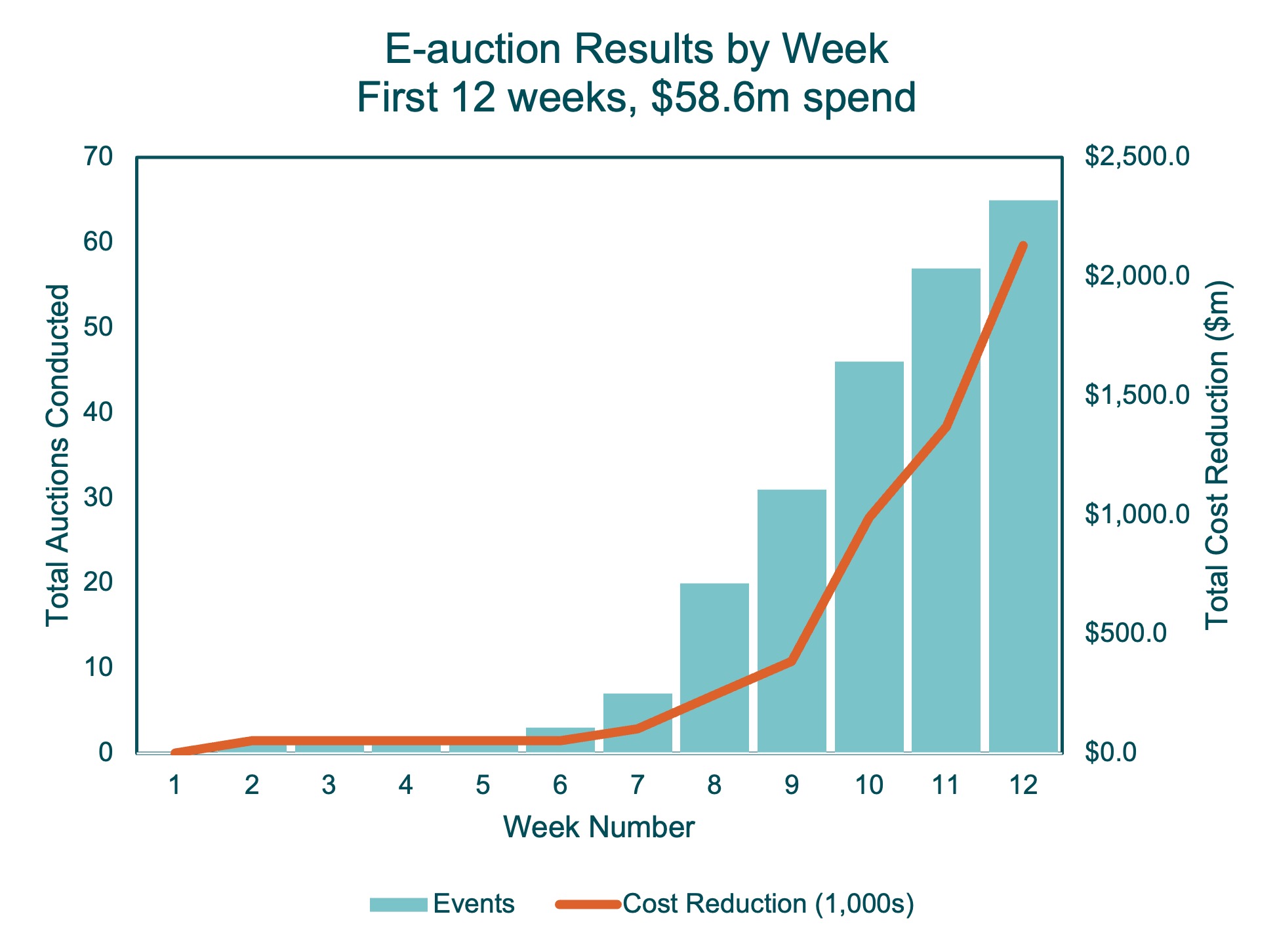

My first client started in November 2024 and was a large midwest utility. They were looking to implement a full e-auction program, and they sure did! They ran their first e-auction in January, had a little time to digest the results and make tweaks to their process, and they onboarded the e-auction team the first week of February. Then they really took off and by the end of the year they’ve run more than $1.3 billion through e-auction and captured more than $40 million in value (that’s value beyond Request For Proposal/RFP savings!). Their total supply chain is around $8 billion in spend, just for a sense of scale. I loved so much watching that team grow, teaching them how to talk to stakeholders (both internal and external), and seeing their amazing victories with this negotiation tool. We used their existing software and because I’ve been through it before we did it so much faster and with better value than I did my first time around (when I had no guidance or help). Everything I’ve seen puts incremental e-auction savings at about 2.5%, but they were at more than 3% additional reduction and were getting those results only a few weeks in. I’m not sure of their total number of auctions run in 2025, but it’s over 400 and I’m sure next year will be even better. That means the Return on Investment (ROI) on that team was around 2000% for their business.

My second client was a small window manufacturer based in Phoenix with a team that was fairly new to supply chain. They had a parent company that expected a lot of the smaller team, but wasn’t providing a lot of guidance. My role was to train the team, mentor their manager in her first leadership role, and launch a category management category. We started with an overview of the supply chain cycle and did a team and self-assessment of which categories needed a deeper dive. Next we did more targeted training and discussion on Sourcing, Order Generation, and Performance Assessment. Then we took the parent company’s 20-slide PowerPoint on category strategies and right-sized it for a smaller, growing team. Each member of the team created a category strategy with the template and then had a one-on-one session with me to refine it, fill in gaps, and consider things they might have missed. It was really neat to watch each team member really start to understand commodity indices, global forces, and how their categories fit into their company as a whole. In a recent email that leader wrote to me, she said, “I wanted to thank you again for all your training and support! The team and I are very grateful for the sessions with you and they still talk about your strategies” which is just so gratifying!

My third client was the first time I joined forces with another firm, the German firm Kloepfel Group, to help a chemical manufacturing client. One of their strengths is really using AI to analyze spend and process invoices, which was needed when this client had very messy data (yes, most companies have messy data. This was maybe worse than usual). For the U.S. side of the client’s business, we negotiated $461,000 in savings on $6.5 million in spend, when the goal was $259,000 in savings. A good chunk of that was when I sourced a dramatically less expensive chiller to rent while waiting for a 24-month lead time on purchasing a new chiller. This whole experience was very interesting because the team was mostly German, the client had branches in the U.S. and Germany (a big part of my role was to understand U.S. procurement culture), and the client went through multiple procurement leaders for the spend we were working on in the time we were working. I learned a lot about working as part of a consulting team, what works and what doesn’t, and how I could maximize value for the client in that space.

My fourth client in the year was the Center for Industrial Research and Service (CIRAS) at Iowa State University. I worked on supply chain assessments for eight Iowa-based manufacturers and conducted negotiation training as part of their continuing education program. I wrote more about the eight manufacturing companies in this article. I found about $2-4.6 million in savings opportunities and trained over 40 people in negotiation. The highlight of the negotiation training for me was putting together realistic real world scenarios and having the attendees spend a good chunk of the training time actually practicing the techniques they had just learned.

My fifth, sixth and seventh clients are all in partnership with Synertrade, who provide both a procurement software platform and do some consulting services using that platform. The fifth client was a furniture manufacturer and we ran an RFP for their biggest direct material category: lumber. Through that process and using their platform, we provided a savings of more than $358,000 on $3.7 million in spend to source eight of their plants with another supplier. There was also an additional potential $152 million in value available due to reducing warehousing and freight costs once the dust settled. They elected not to do an e-auction, but I suspect we could have gotten at least another $30,000 for them using e-auctions as well as being able to group plants using whatever criteria they desired (geographic, by product type, etc.) and consolidate suppliers.

My sixth client is an equipment manufacturer and we are running five e-auctions for them. They are seeking to re-source some business due to all the geopolitical factors at play and this one has been a challenge. We started with castings, and that was not very successful for a couple reasons. First, it will take a while for the casting capacity globally to catch up to all the recent geopolitical changes. It takes a while for a really high quality plant to be built, labor trained, and tooling complete. So there isn’t a strong competitive market all vying for this business that makes for a successful e-auctions. Second, and this is the bigger one for me, we didn’t run an RFP ahead of that auction. This is against my own advice and it appears to be a lesson I have to relearn! For U.S. clients, a straight-to-auction format is extremely tricky unless the requirements are crystal clear and have a decent list of qualified suppliers. I needed to run an RFP ahead of trying to auction castings and hope I don’t have to learn that lesson again. We’ve run two other auctions for them for belts and hoses that went better, but I need to keep in mind all the steps in the auction process.

My seventh client is a building materials distributor and I am part of a bigger team for that client. In the team, we have experts in sourcing indirect and direct sourcing, logistics, and an implementation/execution team. I am providing the e-auction expertise, and have built e-auctions and negotiation strategies for personal protective equipment (PPE), fasteners, nails, fleet maintenance, liquidating excess material, desktop computers, and bottled water. It’s a wide variety of categories, although at this point mostly materials. That client is going through a very large transformation and so they have a lot to deal with as they try to keep things running, transform their business, and convince the skeptics all at once. We met the client’s very aggressive savings goal for 2025 and the core team of five of us (plus support and execution team members) have run about 40 events for them. My work as part of that team is ongoing as we find more opportunities for e-auctions.

Writing

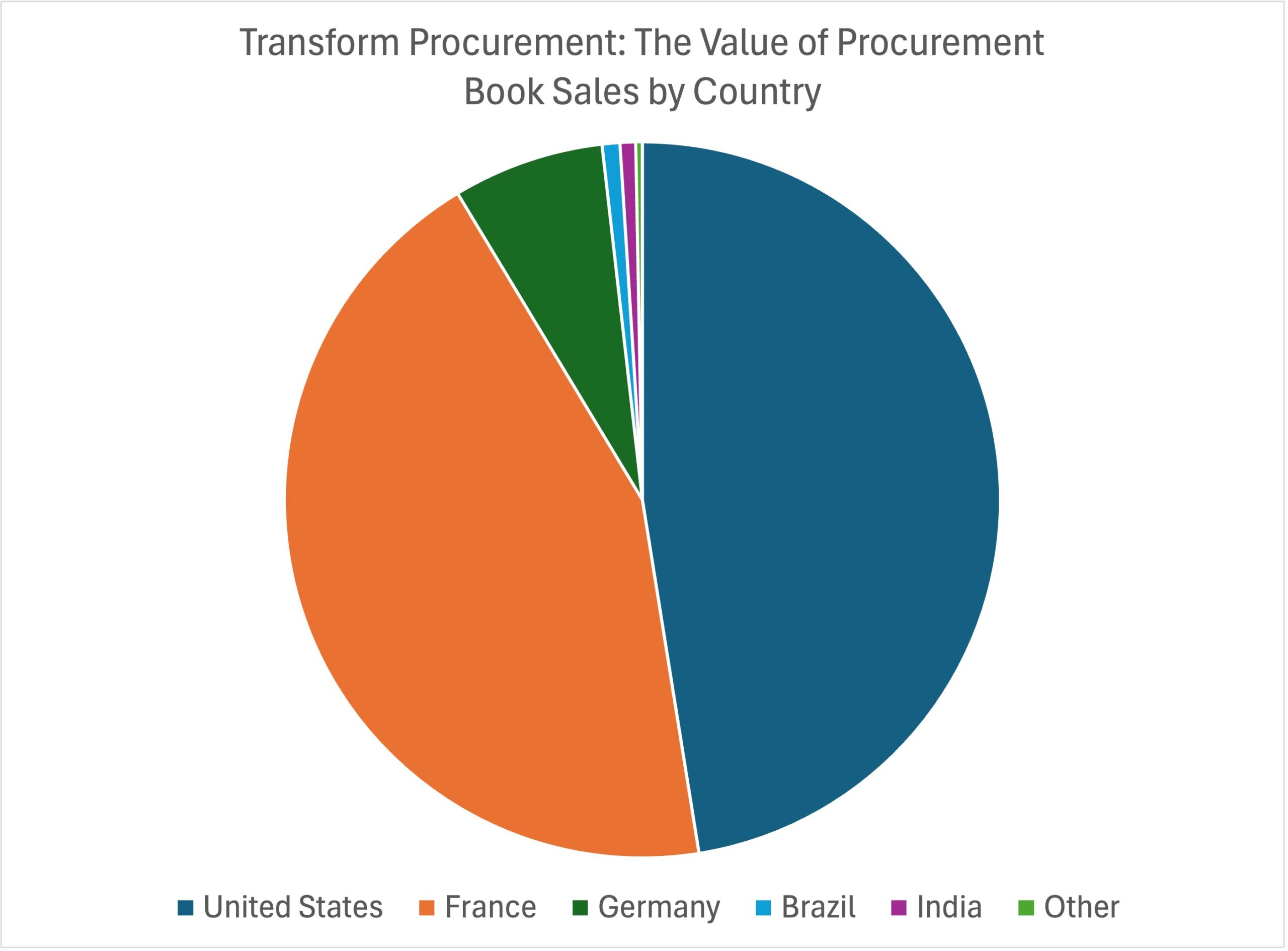

I published a book this year! With the help of Red Thread Publishing, Transform Procurement: The Value of E-auctions made it into the world in May. If you don’t have a copy yet, digital and print copies are available on Amazon here. There are many more of my thoughts on writing and publishing my own book in this post. Looking at my data for the year, I sold about 500 copies this year. The majority of these were for conferences, but there was some interesting international data in my report. I had almost as many royalties from purchases in France as I did in the U.S. This is probably because a large portion of the Synertrade team is located in France and I was also nominated for a book award by Les Plumes des Achats (I’m not sure how that award works entirely. If their website is in order, I took 5th place).

And yes, I used a pie chart to depict this data. I know they’re evil. I partly used one here because the exact numbers are completely unimportant. I’m sorry, I’ll try not to do it again…

Coming up next year I’m working on a chapter in an anthology on female-founded businesses. I’m not sure when it will be published yet, but it should be published some time in 2026. I’m also still trying to figure out what my next book should be about.

I also had a full year of writing weekly posts on a variety of supply chain and leadership topics. My top three articles based on LinkedIn impressions are:

3. Pitfalls of a New Supply Chain Leader

2. Des Moines to Dubai: Highlights and Insights from Passwall Solutions in 2024 (yes, this is basically this post from last year!)

My top-performing supply chain post was What Makes a Manufacturing Supply Chain Unique.

I think it’s interesting these articles are so heavy on career moments, so hopefully I’ve been able to help move someone’s career forward. My goal is always to teach readers something and help you come away with something you can use in your daily life.

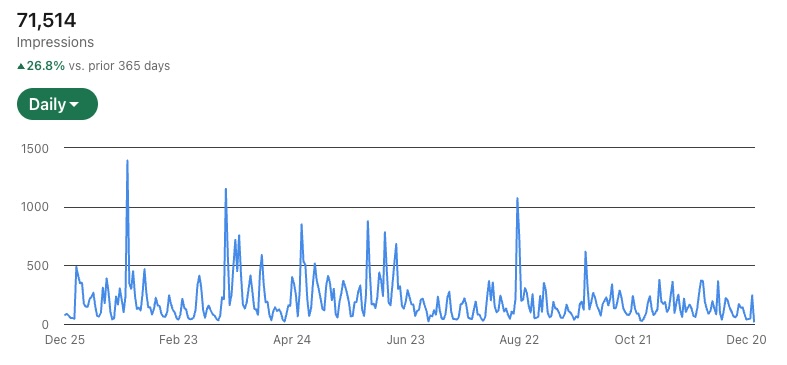

I averaged about 1,375 impressions per week, but am definitely seeing an impact from whatever LinkedIn did to their algorithm in about June. No one has really figured that out yet, but if you spend any time on LinkedIn among people who post regularly, there’s quite a bit of chatter about it.

The regular spikes in this graph are Tuesdays when my weekly article posts, and I don’t have a “weekly” option for this graph.

This was also the year I started a newsletter, which is nice because it’s a bit separate from the algorithms. Interestingly, the highest click rates are very similar to the LinkedIn impressions (being an intern and new supply chain leader pitfalls).

Miscellany

There were a few other things that happened this year as my business matured. First, I worked with the completely talented Doug Choi to get a grown-up logo. My first logo was fine, but I’m not even going to post it here. It was… rough. But it was also basically free (my dad drew it up using his Adobe Photoshop license after I sent him a sketch) and it worked for a little while. Here are the three finalist logos, did I pick the one you would have?

It’s fun to look back on the other ones, I’m still glad I chose the one I did (the one on the right, because you might not have visibility to my logo right now depending on what platform you’re using to read this).

I also got more involved in the North American Women Business Owners (NAWBO) Iowa chapter board. This group of ladies has been a really great set of connections and I love the companionship and wisdom they bring to my business. If you are a woman who runs your own business, consider looking into your local NAWBO chapter. And if you’d like an intro to the Iowa chapter, let me know and I’ll bring you along to one of our coffees or educational lunches.

Lastly, 2025 was the year I started going to conferences again. I had the resources, sponsorships, and ability to do so, so I did. When I was in corporate, I worked for companies that didn’t really believe in sending supply chain leaders to conferences. But this year Synertrade sponsored me for ISM World and Auxionize sponsored me for ProcureCon East. I sponsored myself for SIG and Advancing Construction. Next year I’ll probably go to ISM World, USMA, DPW New York, and at least one SIG event. My writeups for the conferences can be found in the articles below if you’d like to know more:

Tariffs Will Settle At About 10%: An ISM World 2025 Keynote Roundup

Notes from ProcureCon East 2025: Leading Teams and Tariff Strategies

SIG|ORG Fall Summit 2025: Bucket list goals, Agentic AI, and the Iron Triangle

Convince the Skeptics (From Advancing Construction)

If you’re heading to any of these conferences next year, let me know and let’s meet up for coffee or just a chat!

I hope your 2025 was productive in all the right ways (or less productive if you needed to step back). And I hope you achieve all your goals in 2026.

If you would like to talk about your year past or year coming up, let’s chat. If you’d like to get these articles weekly straight to your inbox and never miss one, sign up for my newsletter.

My book, Transform Procurement: The Value of E-auctions is now available in ebook, paperback and hardcover format: https://www.amazon.com/dp/B0F79T6F25