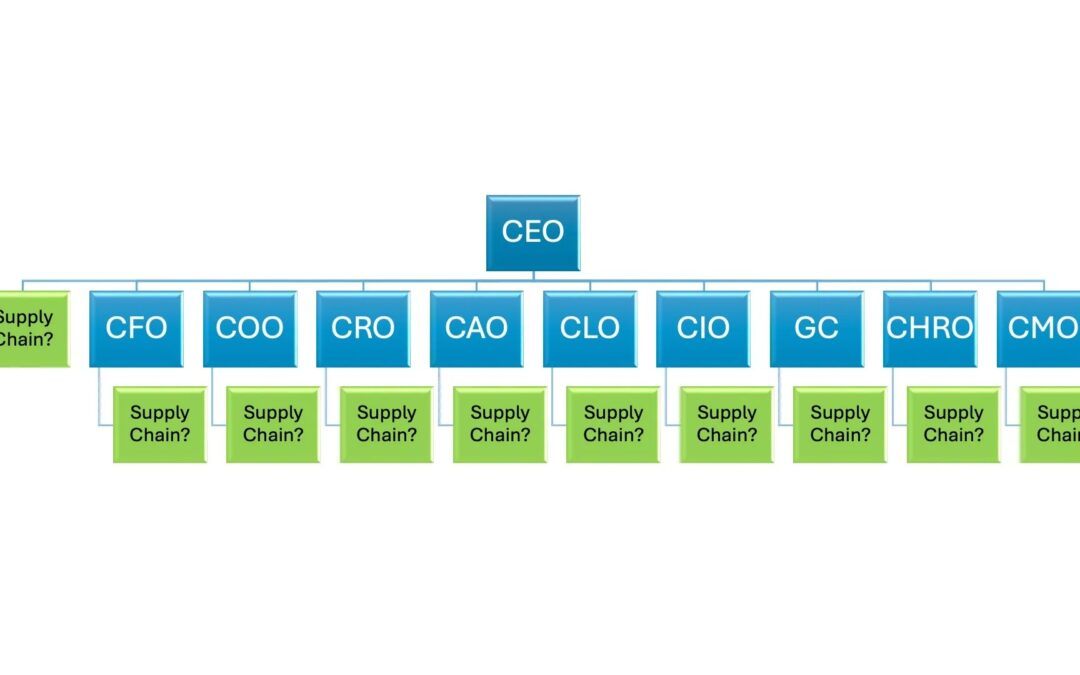

An experienced executive and mentor of mine once told me, “Every org chart fixes some problems and creates others.” I saw this happen firsthand when I was the leader of a 150-person team, with members from multiple businesses within a conglomerate company. The discussion of that organization and centralized vs. non-centralized supply chain is for a different article; the discussion today is about who the supply chain leader reports to. Each option creates both opportunities and issues, and I’ve seen many of these play out in multiple types of organization. Note that all of these are based on generalities, and every organization has that one executive who seems out of place, but is actually perfect for their specific seat. Or is the right-hand person to the CEO and therefore doesn’t fit any of these models. So take these thoughts with that grain of salt and remember there are exceptions to every rule. Let’s talk about the more common C-suite roles and the pros and cons of putting them as the head of the supply chain organization.

Chief Executive Officer (CEO)/President

Starting at the top, the Supply Chain or Procurement team might report directly to the CEO or President of an organization. This might mean the supply chain leader is a Chief Supply Chain Officer (CSCO) or Chief Procurement Officer (CPO), but that isn’t required. Especially in organizations without many C-level titles, a VP of Supply Chain or Procurement can work well reporting to a CEO.

Advantages

Reporting directly to the CEO elevates the supply chain in the eyes of an organization and awards them more freedom to be a true value partner. The supply chain team gets better visibility to what the CEO is really prioritizing at any given moment, and has the highest level seat at the table available. When they need to go toe-to-toe with Finance or Operations, the Supply Chain leader can do so.

Disadvantages

The disadvantage of reporting to the CEO is that the CEO is not likely to have much understanding of the supply chain and is being pulled in many different directions at once. That means the supply chain leader must be a very strong leader who cultivates trust and a high level of autonomy with the CEO. An individual new to an executive role might flounder a bit without an experienced executive to help guide them.

Considerations

Ensure the supply chain leader is not the “lowest ranked person at the table” in the CEO’s staff meetings. I have seen situations where the President or CEO decided to put the supply chain leader in their direct reports, but that leader carried a Director title while everyone around them carried a VP or SVP title. This is like creating all the disadvantages of reporting to a CEO (lack of specialized engagement) without any of the advantages (being able to stand up to peers as an equal). If the CEO’s direct reports generally have C-Suite titles, the supply chain leader must also carry a CSCO or CPO title.

Chief Financial Officer (CFO)

It is fairly common to find supply chain or procurement teams reporting up through the CFO, especially in service-based or software organizations.

Advantages

A supply chain or procurement team reporting up through the CFO will be very focused on the company’s financials. In a recent article by Lora Cecere on her site Supply Chain Shaman, she asserts margins should be the pinnacle metric to measure a supply chain. Having a supply chain leader report directly to the CFO ensures this focus and also tends to drive cost savings. On the iron triangle, a supply chain leader reporting to a CFO is probably focusing on cost and then focusing on either speed or quality depending on the organization.

Disadvantages

As with many C-suite leaders on this list, the CFO is unlikely to have a background in supply chain. The CFO is even less likely than some, as a good CFO probably has accounting or finance certifications (such as a CPA) and has not had the opportunity to deep dive into other areas of an organization. Team members in a CFO’s organization also tend to focus on costs and numbers to the exclusion of all else. That may mean the supply chain team does not focus on value or building supplier and stakeholder relationships. For an organization where the supply chain is only responsible for direct spend and cost cutting is the only thing that matters, this can work well. But to build greater supply chain value, the CFO’s organization can be a tricky place to be.

Considerations

A leader who is very “numbers-oriented” can do well in a CFO’s organization. This might be a finance, accounting, or engineering major in college, or simply someone who has always been analytical. If a supply chain is struggling with its organizational relationships to the point where they cannot make progress, consider putting the team under a leader other than the CFO so they can focus on rebuilding influence instead of driving numbers.

Chief Operating Officer (COO)

The most common place to find the supply chain team in a manufacturing company is under the COO. Due to the nature of the business, the COOs in these organizations often hold the most actual power in the C-Suite (other than the CEO) and lead the largest group of employees.

Advantages

A supply chain leader reporting to the COO will prioritize throughput. Referring again to the iron triangle, a supply chain leader reporting to a COO will prioritize speed and then either cost or quality depending on the organization. The role of a supply chain leader reporting through operations is to keep the line running, at almost any cost. I’ve seen supply chain leaders buy commercial airplane seats for boxes of parts, to sit next to a technician flown out to pick them up. If the organization’s biggest fear is having a lack of parts bring the production line down, the operations team is a great place for the supply chain team to be. For organizations with warehouses and logistics teams, those teams are most likely to report to the COO. This means the entire supply chain reports up through one leader and that leads to efficiencies and understanding between the teams. The COO is also the most likely C-suite leader to have supply chain experience in their background, so is more likely to have a deep understanding of what drives a successful supply chain.

Disadvantages

While a good COO won’t let supply chain costs run rampant, expediting parts and prioritizing speed will come at a cost. Supply chain teams who report to an operations leader may not prioritize cost savings, so those savings can be lower under the operations leader than other leaders. I have also seen COOs use their power as a bully pulpit against their peers, weaponizing the supply chain into a compliance police force in the name of production continuity instead of a stakeholder partner.

Considerations

At most organizations, operations is a more 24/7 role than in other areas. If a supply chain leader reports through the COO, they need to either be aware they may get phone calls during the second or third shift, or they need to be able to set clear boundaries on their time to preserve work life balance. Hiring managers for supply chain leaders also need to be aware of bias due to this “always on call” approach and not discriminate against women for these roles under the assumption that they are a primary parent. Be clear about “on-call” expectations and let the candidates make that decision.

Chief Revenue Officer (CRO)

I have occasionally seen a supply chain leader report to the CRO or sales leader, which is an interesting place to put a supply chain leader.

Advantages

If the supply chain leader reports to the CRO, they tend to keep a closer tie to the customer. For organizations that struggle with demand planning or getting the “pull” from the customer well-mapped, tying supply chain directly to sales can help with that demand signaling. Reporting to the CRO also really helps the supply chain understand what the customers want and need, and what they struggle with. It makes it more likely the supply chain team will focus on the quality dimension of the iron triangle because high quality makes customers happier.

Disadvantages

Putting the supply chain leader under the CRO bloats inventory. This happens because the CRO’s priority is to make sure the customer has enough product, and that their sales team is never empty-handed in fulfilling promises. For an organization with sufficient cash to cover excess inventory, this may be fine. Focus on the quality component of the iron triangle also means less emphasis on speed or cost. Both of those things can easily spin out of control if not watched, which goes hand-in-hand with the excess inventory.

Considerations

A supply chain leader reporting to the CRO must either already have good customer service skills or need to learn them (and have a patient CRO to teach them). If the organization is really trying to emphasize a customer service mindset, putting the supply chain leader under the CRO can help that effort.

Chief Administrative Officer (CAO)

The CAO is an interesting role, and not many businesses have one. Putting the supply chain under the CAO often says a lot about the supply chain’s role within the organization.

Advantages and Disadvantages

I’m looping advantages with disadvantages for reporting through the CAO role because this one is mixed. Supply chain reporting to the CAO is a little like putting the team in purgatory, where they more exist than move the organization forward. The team is firmly in a support role where they don’t have enough power or clout to make operational changes that will result in a better supply chain, and they aren’t part of the inner workings of the company’s financials. If the CAO is an excellent leader, this can be a good place to put the supply chain team as it’s a bit of a flexible, generalist spot. Whatever the supply chain needs to be, unless that need is to be powerful, can be accomplished from the CAO’s organization.

Considerations

A very autonomous supply chain leader will do well under a CAO, if reporting to the CEO is not a good option. The CAO likely doesn’t have a strong supply chain background, and is probably also leading all the “cats and dogs” of the organization. So similar to reporting the CEO, reporting to the CAO takes a great deal of autonomy.

Next week’s article will explore some of the less common spaces for supply chain’s reporting structure, including the Chief Lean/Optimization/Continuous Improvement Officer, the Chief Information Officer, The General Counsel, the Chief HR/People Officer, the Chief Marketing Officer, and configurations where the supply chain is split across multiple pillars.