I first encountered Foreign Trade Zones (FTZs) and bonded warehouses while working for a manufacturer who was getting many components out of China. Before that point, most of my employers were getting the majority of their shipments domestically, either from US manufacturers or through distribution. FTZs and bonded warehouses are a fascinating approach to importing materials, don’t show up often in online chatter. Today’s article I’m talking about the basics of bonded warehouses and FTZs, with a few resources added to help me out as this is not my “bread and butter”. If you’re interested in learning more, work with your third-party logistics provider for better expertise. I highly recommend Bronco as an excellent 3PL partner, especially in this space and especially if you are importing many materials from Mexico to the US.

Basic Process

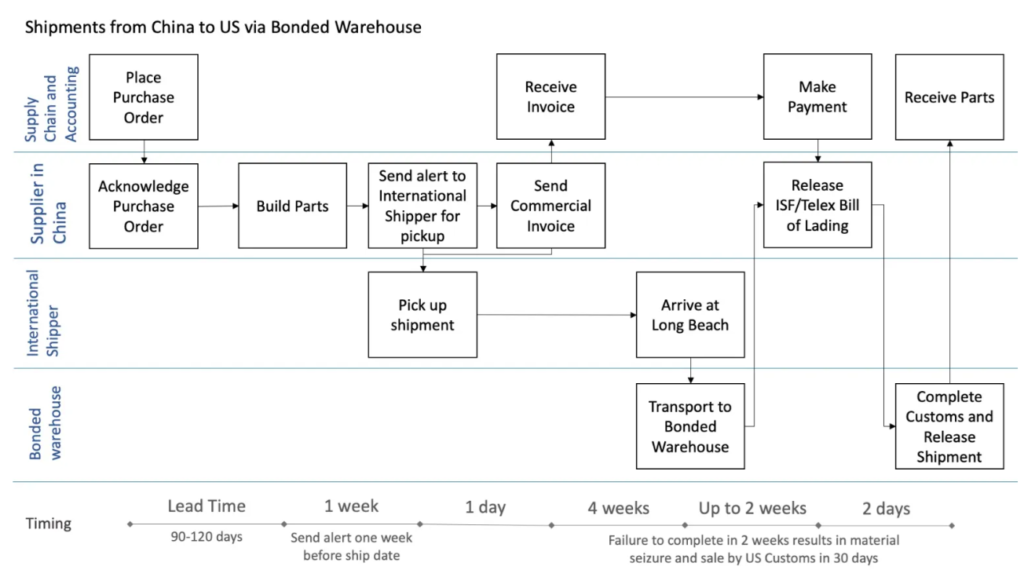

The basic process of shipping from China to a US bonded warehouse is above, with “swim lanes” showing each team’s role. In this case, the shipment is going to Long Beach, California. The bonded warehouse or FTZ processes are very similar to standard shipments from another country, but what they do is buy time to pay customs fees. An FTZ adds the benefit of allowing a company to do some manufacturing within the FTZ, more on that in the comparison below. The basic process of using a bonded warehouse is:

- The supply chain team places the order as usual

- The supplier builds the parts and ships them (or the buyer arranges shipping depending on your choice of Incoterms)

- After arrival in the US, the buyer has 2 weeks to settle paperwork with customs.

For an FTZ, the FTZ is considered to not actually be in the US commerce market until released, so it’s as if goods exist in a purgatory “bubble” outside of the flow of trade.

Bonded Warehouses vs. FTZs

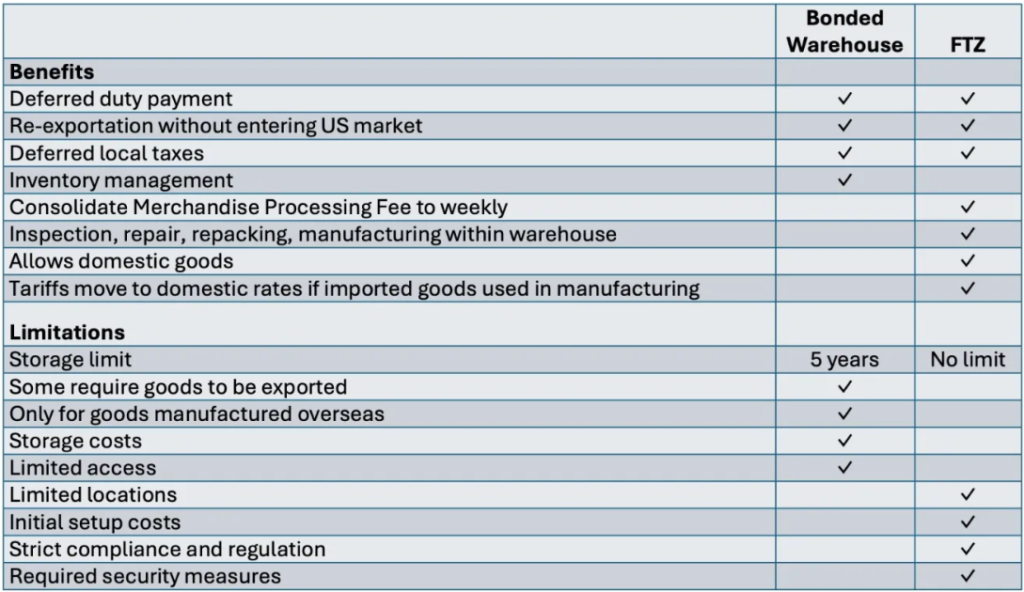

Bonded warehouses and FTZs are certainly different, with more information found in this Thomson Reuters article. (Huge side note: I just listened to the story of Paul Julius Reuter on the Stuff You Missed in History Class podcast – fascinating stuff!)

Below is a table summarizing the differences between bonded warehouses and FTZs, both in benefits and their limitations.

The unspoken component of using these import tools is adding in a little certainty to political uncertainty. The US administration recently announced new tariffs for electric vehicles, but there is a lag between announcement and effective dates. Nimble businesses or those with FTZs already in place can potentially use this lag time to import products under the previous rates, or to hold goods purchased after those rates are in effect hoping a new administration might reduce tariffs. It’s always risky, but FTZs especially can help smooth an otherwise bumpy tariff ride.

What Bonded Warehouses and FTZs are not

In the company I worked for, my CEO had a misconception that payment was not required to the supplier until the goods were removed from the bonded warehouse or FTZ. This is not the case as the import paperwork needs to be settled fairly quickly once the shipment arrives, and most suppliers do not release paperwork until payment has been made.

Neither bonded warehouses or FTZs are low cost options for component storage. While they may save money overall when evaluating a total cost of ownership, especially if you can complete value-add activities within an FTZ, they are not short-term solutions and are certainly more about value than immediate savings. To talk through your logistics or supply chain strategy, schedule some time on my calendar and let’s chat.