The what-about-ism in e-auctions runs strong, and nowhere does it run stronger than the question “What about if an e-auction becomes a race to the bottom?” In the early 2000s, e-auctions often did become a race to the bottom. There was no Request for Proposal (RFP) before the e-auction. Criteria for the award was muddy or was different for different suppliers. So how do we combat this issue? The answer is with go/no-go criteria.

What are Go/No-Go Criteria and Why Use Them?

I’ve mentioned go/no-go criteria in my article on writing a scope of work and again in my article on how your RFP might be driving away great suppliers. Go/no-go criteria, which I’ve also heard called knockout criteria, are simply what they sound like – criteria by which suppliers are either a “go” or a “no-go”. A pass or fail. A yes or no. They are as simple as turning bid evaluation criteria from “How many years of experience in this industry do you have?” into “Supplier must have ten years’ experience in this industry.” So why use go/no-go criteria?

- A supplier knows immediately what the buyer requires and what will get them disqualified. They don’t have to waste time responding to an RFP they know they cannot win.

- It forces the technical team to consider what is truly important. Creating criteria that will instantly disqualify a supplier requires careful thought and really crystallizes the need.

- When it comes time to negotiate, you are more likely to have an apples-to-apples comparison between options. Some suppliers tend to like to include “extras” in their bids beyond what is truly required. While they often say these are offered at no charge, removing all these extras can magically lower their costs. Go/no-go criteria helps suppliers focus on what matters or make a clearer argument that their extras should actually be requirements for all bidders.

- Clear and transparent criteria make your bid more fair. The suppliers are all competing for the same business, using the same criteria, and they all know what that is. That will automatically help focus on the product or service the suppliers offer instead of everyone trying to “out-game” the RFP process.

When and How to Use Go/No-Go Criteria

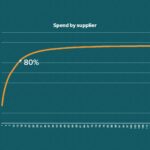

I believe every major RFP should have firm go/no-go criteria. What constitutes a major RFP? That differs for every company and procurement team. I would generally consider a major RFP to be one for a top spend category (not tail spend), is moderate or high risk, and is generally considered to be strategic for the business. This might be a capital project such as a building or equipment expansion, a key direct material used in manufacturing a product, or even a periodic bid for plant services. Some things to consider in using go/no-go criteria:

- Write your criteria such that even one “no” disqualifies a supplier. This means you probably want no more than 6-8, and even that can be too many.

- Try to use jargon-free language. Spell out all acronyms, even if you or the technical team considers them industry standard.

- Watch for too many criteria creeping in from departments other than the technical team. This might mean the safety, cybersecurity, or legal team. Try to limit each of them to one thing that truly matters to them and for which they would be willing to fight to disqualify a supplier.

Side Note: I’ve definitely worked on a team where cybersecurity got to the point where they had five or six go/no-go criteria on every bid we sent. While the cybersecurity position of the company was important and a stated priority directly from our CEO, I also observed that the cybersecurity team would bend under pressure to award suppliers who had a “no-go” to one of their criteria. Not only does this undermine the entire list of criteria, it meant not all those criteria were truly go/no-go. For example, our cybersecurity team required a SOC 2 audit. But if pressured because a supplier otherwise met all criteria, they would relax their requirement to require a SOC 2 audit within a year or year and a half. How many other suppliers would have put forth excellent proposals if they had always known they would have 18 months to complete this requirement?

Examples

So now that we know what go/no-go criteria are, why, where, and how to use them, let’s get specific. Note that there are more examples in Chapter Seven of my book.

Poor criteria: Supplier will have experience in projects like this scope of work.

Why it is poor: This criteria is vague and hard to measure. What is “experience”? Does it count if the supplier was working alongside another firm to do something like what you are asking for? How alike does the experience need to be? How will the buyer know the seller is truly offering what is needed?

Better criteria: Supplier cites two projects similar to this scope, with customer references.

Poor criteria: Supplier offers a 602-horsepower bulldozer.

Why it is poor: This is one of my favorite examples and if you ever hear me speak, I’ll probably use it. This seems so good! It is clear, you can measure it, and it’s very specific! So what’s the issue? Chances are very good this comes directly from a manufacturer’s specification. It’s likely there is only one manufacturer whose bulldozer is exactly 602 horsepower. While making this a range of numbers would be a little better, it also fails to speak to the true need. What does the technical team need this bulldozer to do? In my farm business, I’ve seen 40 horsepower tractors that can run large hay bales in circles around the cattle lot with no trouble and those that struggle to lift that same bale off the ground. Horsepower isn’t everything, and chances are good there’s a specification like this hiding somewhere in your scope. The hard part is to know where to look and find it.

Better criteria: Supplier offers a bulldozer with at least a 35 cubic yard (27 cubic meter) payload.

Poor criteria: The supplier has minimal redlines to contract terms.

Why it is poor: This is similar to the previous poor criteria: it’s vague and hard to define. We all know what a contract with “lots” of redlines looks like. But what is “minimal”? One redline? What if it’s only a few redlines, but those are truly awful? (Instead of a 5-year warranty, we offer 6 months!) On the other side of the spectrum, what if there’s a bunch of redlines, but none of them make major changes to terms or those changes are standard and acceptable (i.e. Delaware jurisdiction instead of wherever the buyer is headquartered).

Better criteria: The supplier offers at least a five-year warranty and a liability limitation of no less than the insurance limits in the contract terms. (Or whatever criteria is most important to your business.)

Things That Go Wrong (and what to do about it)

Like seemingly everything in supply chain, go/no-go criteria can go wrong. Here’s how that tends to happen and some things you can do about it.

- The criteria result in only one qualified supplier (or no qualified suppliers) after evaluation. This happens when a technical team writes the criteria (intentionally or unintentionally) so their preferred supplier wins, often the incumbent. Your choices in that case are: to continue a negotiation with the single qualified supplier, or modify the criteria and scope of work and send it back out for another round of bids. Keep an eye out for very limiting criteria when setting them initially and don’t be afraid to challenge a technical team if the criteria is too limiting.

- Poor (or poorly-written) criteria cause a bunch of questions. This is when a disqualification criteria contains too much jargon, is vague, or is something the incumbent supplier “just knows.” The best path here is to just answer the questions and publish answers to all suppliers (removing anything identifying the supplier who asked the question). You’re allowed to be human and simply send out a clarification during the bid to make that criteria better. Ensure the same communication goes to every supplier as much as possible.

- One supplier makes a strong argument that something should be added to the go/no-go criteria. In this case, start by making sure adding this criteria doesn’t make it so only one supplier is qualified. Does the technical team truly need that added feature, or should it be priced as an option? If you decide to add it to the go/no-go criteria, make sure all suppliers get a chance to consider it and adjust their bids accordingly. If this happens after bids are collected, ensure even suppliers who chose not to enter a bid are aware of the change and are offered the chance to bid. It’s possible they didn’t enter a bid initially because without that requirement, they knew they couldn’t compete.

Most of these issues with go/no-go criteria get better with a procurement professional who knows just a bit more about the category and who has good communication with the technical team. Procurement professionals don’t have to be technical experts, but they should know enough about a category that they can spot those poor criteria when they show up.

If you don’t already, try using firm go/no-go criteria on your next bid. You may just find it helps bids be more fair, balanced, transparent, and competitive. If you’d like to talk through your proposed criteria, let’s chat.