The hot topic in supply chain for the last few years has been supply chain disruption. Supply Chain Brain’s annual supplier partnership publication is themed around disruption, everyone working anywhere in supply chain in 2021 remembers what working through disruption looks like, and continuing global conflicts impact everything from grain to nickel. Executive leadership teams are continually asking their supply chain teams to predict disruption, and multiple software companies are offering to sell better solutions and “AI” to predict supplier disruption. While software solutions can be very helpful to map second and third tier suppliers in your supply chain and their origin points, I advocate first for simpler solutions. Before purchasing a higher-level package, most businesses should first master four major sources of supplier disruption: ERP system go-live, weather events, political elections, and holidays.

ERP System Go-Live

Having a supplier implement or upgrade their Enterprise Resource Planning (ERP) system is not a frequent occurrence, but it is hugely disruptive. With SAP only supporting their Business Suite 7 through 2027 (And Oracle using this to commit to supporting their E-Business suite through 2035), businesses everywhere will be going through an ERP transition in the next ten years. Most of my clients are smaller or more specialized, and don’t even use one of the big ERP systems. They are increasingly finding that their ERP programs are simply not up to the task of managing their supply chains, inventories, and customers, and so they have an eye on switching ERP systems.

In my very first procurement role, I learned quickly that a supplier changing ERP systems was about to undergo a major disruption. No matter how insistent they were that things would be seamless for me, I kept a more careful eye on suppliers upgrading ERPs. There are three actions to take here:

- Have a good enough relationship with your key supplier(s) that you can ask about any ERP upgrades or implementations, and get their go-live dates.

- If at all possible, slowly purchase enough product to be delivered ahead of that supplier’s go-live date to last 6 months without any deliveries from the supplier. If space, cash, or anything else is an issue, get as much extra inventory as you can to last at least a month without receiving anything from that supplier. If their go-live goes poorly, they may disappear off the planet for a moment and you don’t want your own customers to be disrupted. If given enough warning, build up this extra stock gradually ahead of the go-live date.

- Continue placing small orders with the supplier after go-live until things seem to be running well. Offer grace with issues and keep communication very high on the issues they are seeing and how you can help. If you business can afford to, consider offering shorter payment terms temporarily while your supplier gets through their rough patch.

Weather Events

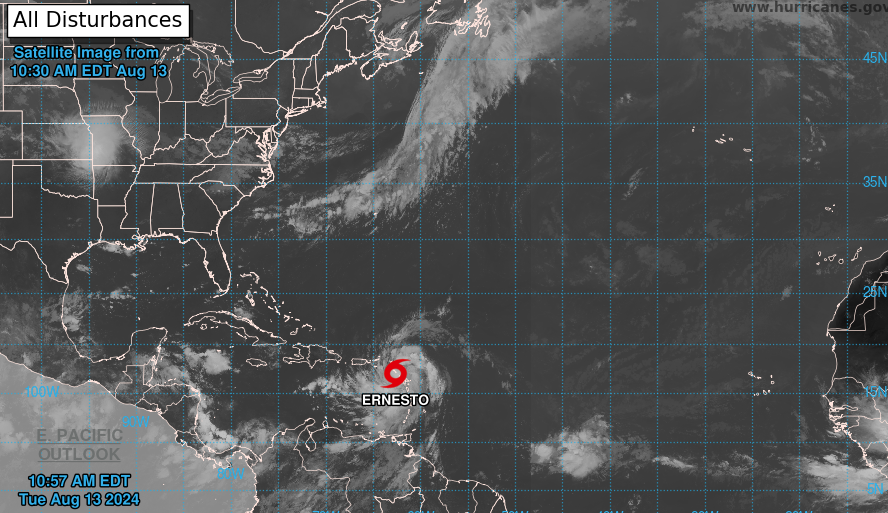

Weather happens. While some events, like earthquakes and volcanoes, are fully unpredictable, others have seasons. Hurricanes/monsoons, snow storms, and even sometimes droughts and floods have times of year when they are more common. Hurricanes in the U.S. even typically give at least a few days’ warning. The hard part of weather events is knowing which suppliers are in the path of the event and the part of your business at risk. Keep extra stock of chemicals sourced out of Houston (hint: it’s most of them) or lumber sourced from Georgia heading into hurricane season. Keep extra stock of automotive/machinery components from Michigan heading into snow storm season. When a weather event hits a certain area particularly hard, check on your contacts at suppliers as people. For major events such as the Texas power outages in 2021, your sales reps are far more focused on their family’s safety than if you have your order on time. So offer some grace and don’t be yet another grumpy customer in their queue.

Political Elections

Political elections are a funny thing, and not always something we think of for supply chain disruptions. And the election day itself may not have a huge impact on the supply chain, but the fallout from the election certainly does. Depending on the political party and philosophy in power, there can be major changes in project funding, tariffs, and staffing levels. It is a common pattern that very little moves financially before an election, and then “falls apart” after the election is over. If you work in a particularly volatile commodity or one subject to political movement (such as electric vehicles), keep an eye on election timing and results. Know how those elections are likely to affect the scarcity of your categories.

Holidays

I have found in the United States that we tend to be very US- and Christian-centric on our knowledge of holidays. While that is applicable and relevant for domestic purchasing, international purchasing often follows a very different calendar. Most supply chain professionals know that nothing moves out of China for roughly two weeks around the Chinese New Year, but what about the Dragon Boat Festival in May or June? How about Holi in India or Ramadan and Eid al-Fitr in Islamic countries? Even Christmas can be more disruptive than expected as Pacific shipping lanes fill up ahead of the Christmas shopping season starting as early as September or October. For supply chain professionals working globally to source goods and services, expect major holidays to cause supply chain disruption. Not all supply chain disruptions are predictable or preventable. But before implementing fancy or expensive software to mitigate disruptions, start by asking if you already have programs to predict and minimize disruptions from ERP system go-lives, weather events, political elections, and holidays. If you’d like to talk about your risk mitigation programs, schedule some time on my calendar and let’s frame up a program to get you started on minimizing supply chain disruption.